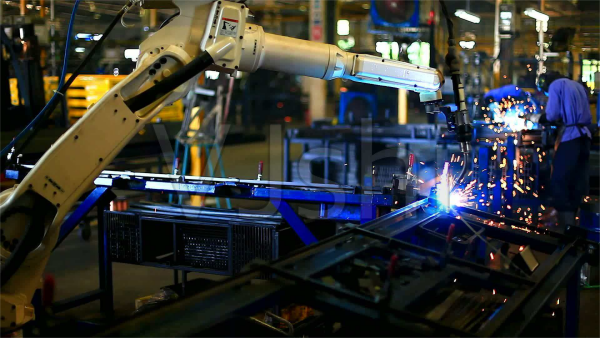

Ɗauki sabbin fasahohin simintin gyare-gyare na ci gaba, da haɓaka aikin sarrafa kayan aikin simintin, musamman aikace-aikacenrobot masana'antufasahar sarrafa kansa, shine babban ma'auni don jefa masana'antu don aiwatar da ci gaba mai dorewa.

A cikin samar da simintin gyare-gyare,robots masana'antuba zai iya maye gurbin mutanen da ke aiki a cikin babban zafin jiki ba, gurɓataccen yanayi da haɗari, amma kuma inganta ingantaccen aiki, inganta daidaiton samfur da inganci, rage farashi, rage sharar gida, da samun sassauƙa da tsayin daka na samar da matakai masu sauri. Haɗin kwayoyin halitta na kayan aikin jefawa darobots masana'antuya rufe fannoni daban-daban kamar simintin mutuwa, simintin nauyi, simintin ƙarancin matsa lamba da simintin yashi, galibi waɗanda suka haɗa da yin core, simintin gyare-gyare, tsaftacewa, injina, dubawa, kula da ƙasa, sufuri da palletizing.

Taron bitar ya shahara musamman, cike da zafin jiki, kura, hayaniya, da sauransu, kuma yanayin aiki yana da tsauri. Ana iya amfani da mutummutumi na masana'antu don yin simintin nauyi, simintin ƙarancin matsi, simintin matsa lamba, simintin simintin gyare-gyare, rufe tarurrukan da hanyoyin simintin simintin baƙar fata da ba na ƙarfe ba, suna rage ƙarfin aiki na ma'aikata.

Dangane da halayen simintin gyare-gyaren, masana'antu robot gravity simintin raka'a sarrafa kansa suna da tsari iri-iri.

(1) Nau'in madauwari ya dace da simintin gyare-gyare tare da ƙayyadaddun ƙayyadaddun bayanai, sauƙi mai sauƙi, da ƙananan samfurori. Kowace na'ura mai nauyi na iya jefa samfura na takamaiman bayanai daban-daban, kuma yanayin tsarin na iya zama iri-iri. Mutum daya na iya sarrafa injinan nauyi biyu. Saboda ƴan ƙuntatawa, shine yanayin da aka fi amfani dashi a halin yanzu.

(2) Nau'in ma'auni ya dace da simintin gyare-gyare tare da sifofi masu rikiɗar samfuri, ƙwanƙolin yashi, da tsarin simintin simintin. Dangane da girman simintin gyare-gyare, ƙananan simintin gyare-gyare suna amfani da ƙananan na'urori masu nauyi. Tashar jiragen ruwa da ke zubowa duk suna cikin yanayin da'ira na mutum-mutumin masana'antu, kuma mutum-mutumin masana'antu ba ya motsi. Don manyan simintin gyare-gyare, saboda daidaitattun injunan nauyi sun fi girma, robot ɗin masana'antu yana buƙatar sanye take da axis mai motsi don zubowa. A cikin wannan yanayin, samfuran simintin za su iya bambanta kuma tsarin tsarin na iya zama mara daidaituwa.

(3) Rashin lahani na madauwari ta gefe-da-gefe da nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan nau'ikan kayan aikin yashi core na sama da simintin gyare-gyaren ƙananan sassa na tashoshi ɗaya ne kuma an warwatse, kuma yin amfani da na'urorin nauyi gefe da gefe yana magance wannan matsalar. An tsara adadin injunan nauyi gwargwadon girman simintin gyare-gyaren da tsarin tsarin, kuma an ƙera robot ɗin masana'antu don sanin ko yana buƙatar motsawa. Za a iya daidaita masu riko da kayan aiki don kammala aikin sanya ginshiƙin yashi da sauke kaya, samun babban digiri na sarrafa kansa.

(4) Nau'in madauwari Gudun simintin wannan yanayin ya fi inganci fiye da hanyoyin da suka gabata. Na'urar nauyi tana jujjuya akan dandamali, tare da tashoshi masu zubewa, tashoshi masu sanyaya, tashoshi masu saukar da kaya, da sauransu. Na'urori masu nauyi da yawa suna aiki lokaci guda a tashoshi daban-daban. Robot ɗin da ke zubowa yana ci gaba da ɗaukar ruwan aluminium don zubawa a tashar da ake zubawa, kuma robot ɗin da za a zazzage yana ci gaba da saukewa (ana iya yin shi da hannu, amma saboda ƙarfinsa, ƙarfin aikin ya yi yawa). Wannan yanayin ya dace kawai don samar da simintin gyare-gyare na lokaci guda tare da samfurori iri ɗaya, manyan batches, da madaidaicin bugun.

Idan aka kwatanta da injunan simintin nauyi, injunan simintin ƙananan matsi sun fi hankali da sarrafa kansa, kuma aikin hannu kawai yana buƙatar yin aikin taimako. Koyaya, don yanayin gudanarwa mai sarrafa kansa, yayin aikin simintin, aikin hannu zai iya kula da layi ɗaya ta mutum ɗaya kuma kawai yana taka rawar duban sintiri. Don haka, an gabatar da rukunin simintin gyare-gyare marasa ƙarfi, kuma robots na masana'antu sun kammala duk aikin taimako.

Akwai hanyoyi guda biyu na aikace-aikacen raka'o'in simintin ƙaramar matsi mara matuƙi:

(1) Don yin simintin gyare-gyare tare da ƙayyadaddun samfura da yawa, simintin gyare-gyare mai sauƙi, da manyan batches, mutum-mutumi na masana'antu ɗaya na iya sarrafa injunan simintin ƙananan matsi guda biyu. Robot ɗin masana'antu yana kammala duk ɗawainiya kamar cire samfur, sanya tacewa, lambar ƙarfe, da cire fikafikai, don haka gano simintin ƙarfe mara matuƙi. Saboda shimfidar wurare daban-daban, ana iya rataye robobin masana'antu sama da ƙasa ko a tsaye.

(2) Don yin simintin gyare-gyare tare da ƙayyadaddun samfur guda ɗaya, buƙatar sanya hannun hannu na sandunan yashi, da manyan batches, robots na masana'antu kai tsaye suna ɗaukar sassan daga na'ura mai ƙarancin ƙarfi, sanyaya su, ko sanya su akan injin hakowa kuma canza su zuwa tsari na gaba.

3) Don yin simintin gyare-gyaren da ke buƙatar sandunan yashi, idan tsarin yashin yashi mai sauƙi ne kuma ginshiƙan yashi guda ɗaya ne, ana iya amfani da robots na masana'antu don ƙara aikin ɗauka da sanya sandunan yashi. Sanya hannun hannu na sandunan yashi yana buƙatar shigar da kogon ƙira, kuma zafin jiki a cikin ƙirar yana da girma sosai. Wasu sandunan yashi suna da nauyi kuma suna buƙatar taimakon mutane da yawa don kammalawa. Idan lokacin aiki ya yi tsayi da yawa, zafin jiki zai ragu, yana shafar ingancin simintin. Sabili da haka, ya zama dole a yi amfani da mutummutumi na masana'antu don maye gurbin tushen yashi.

A halin yanzu, aikin gaba-gaba na simintin gyare-gyare mai mahimmanci, irin su zub da ruwa da feshi, an kammala su ta hanyar ingantattun ingantattun hanyoyin, amma cirewar simintin gyare-gyare da tsaftace kawunan kayan ana yin su da hannu. Saboda dalilai irin su babban zafin jiki da nauyi, ƙarancin aikin aiki yana da ƙasa, wanda hakanan yana iyakance ƙarfin samar da injin simintin. Robots na masana'antu ba wai kawai suna da inganci wajen fitar da sassa ba, har ma a lokaci guda suna kammala aikin yanke kawunan kayayyaki da jakunkuna, tsaftace filaye masu tashi, da dai sauransu, yin cikakken amfani da mutummutumi na masana'antu don haɓaka dawo da saka hannun jari.

Lokacin aikawa: Jul-08-2024